Technology

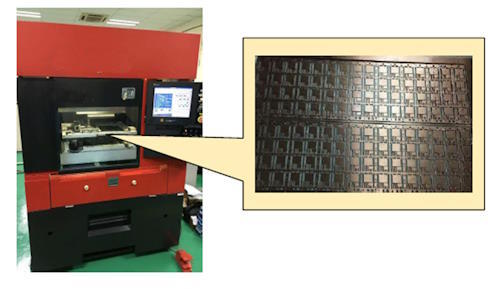

We utilized state of the art technology to ensure our quality achieving satisfactory standard. We developed and implement activities to further secure the standard of quality and towards zero defect initiatives through the use of Automated vision inspection (AVI) and Rapid Prototyping services.

What is Rapid Prototyping?

Rapid Prototyping is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer aided design data. Construction of the part or assembly is usually done using 3D printing or “additive layer manufacturing” technology.

Advantages:

- Rapid prototype sample without the need for expensive tool investment (Tools for Press and Dual Gauge).

- Quick change in design is possible for fast simulation evaluation.